3D Printing and Prototyping: From CAD Model to Physical Product

Advanced 3D Printing and Rapid Prototyping Strategies

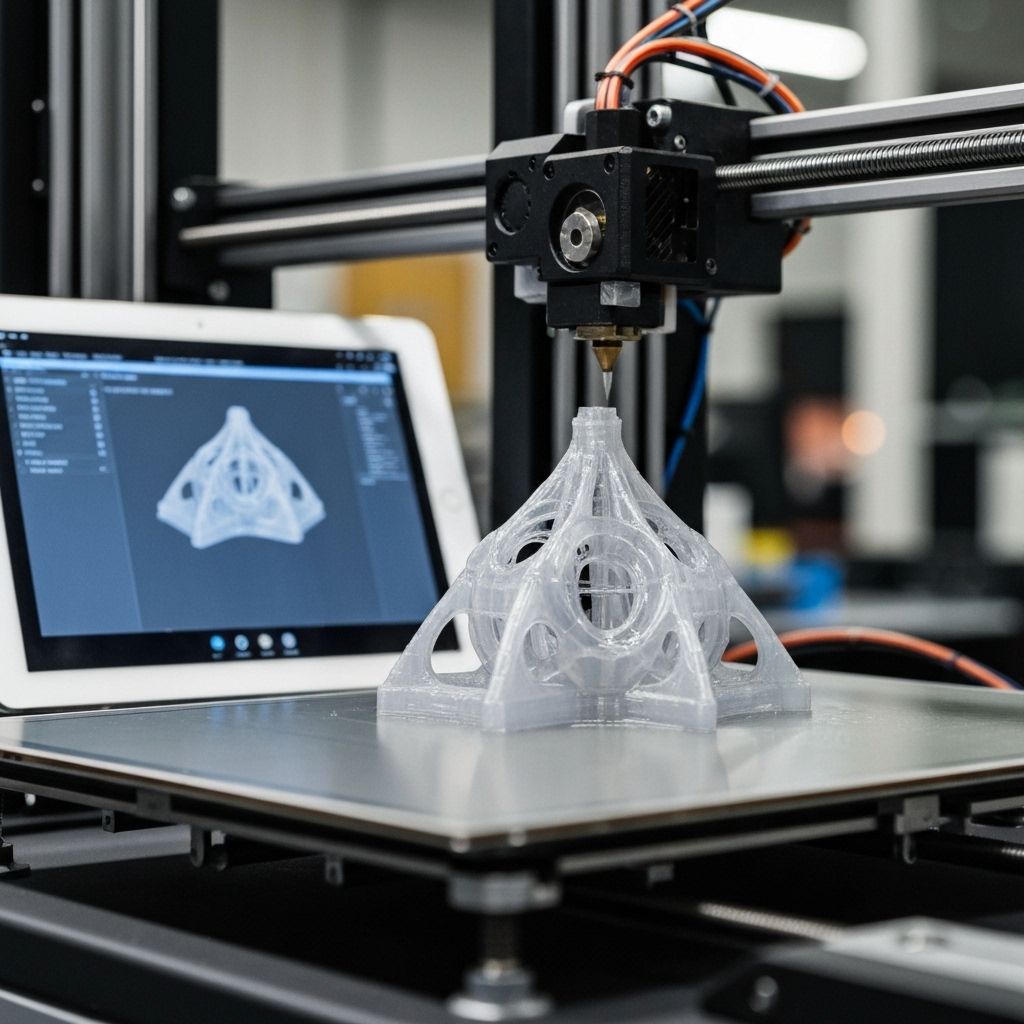

Transforming CAD models into functional prototypes through 3D printing requires understanding of additive manufacturing processes, material properties, and design optimization techniques. As a freelance 3D printing and prototyping specialist, I provide comprehensive services that bridge the gap between digital design and physical validation through advanced additive manufacturing strategies.

Professional 3D printing services enable rapid iteration, cost-effective prototyping, and complex geometry production impossible with traditional manufacturing methods. This expertise accelerates product development cycles while reducing costs and enabling innovative design solutions that push the boundaries of conventional manufacturing constraints.

Design for Additive Manufacturing (DfAM) Optimization

3D printing enables complex geometries impossible with traditional manufacturing, but requires specific design considerations including support structures, layer adhesion, material flow, and thermal management. Optimizing designs for additive manufacturing maximizes prototype quality and functionality while minimizing print time and material usage.

Advanced DfAM techniques include topology optimization, lattice structures, and integrated assembly design. Professional design optimization services create parts that leverage additive manufacturing advantages while avoiding common pitfalls that can compromise print quality and functional performance.

Specialized DfAM approaches encompass multi-material printing, embedded components, and functional integration techniques. This expertise enables creation of sophisticated prototypes that combine multiple functions and materials in single print operations while maintaining structural integrity and performance requirements.

Material Selection and Properties Analysis

Understanding material characteristics including strength, flexibility, temperature resistance, chemical compatibility, and surface finish helps select appropriate materials for specific prototype requirements. Each material presents unique advantages and limitations for different applications and testing scenarios.

Advanced material selection encompasses engineering plastics, metal powders, ceramic materials, and composite filaments. Professional material consulting services ensure optimal material choices that balance performance requirements with printing constraints and project budgets while meeting functional testing needs.

Specialized material applications include biocompatible materials, high-temperature polymers, and conductive filaments for electronic applications. This expertise enables prototyping of sophisticated products that require specific material properties for accurate functional validation and performance testing.

Support Structure Optimization and Removal Planning

Minimizing support material while maintaining print quality requires strategic part orientation, support placement, and removal planning. Proper support design reduces post-processing time and improves surface finish quality while ensuring successful printing of complex geometries and overhanging features.

Advanced support strategies include soluble supports, tree supports, and custom support structures optimized for specific geometries. Professional support optimization services reduce material waste and post-processing effort while maintaining dimensional accuracy and surface quality requirements.

Specialized support techniques encompass minimal contact supports, breakaway interfaces, and automated support generation for complex assemblies. This expertise ensures even the most challenging geometries can be printed successfully while minimizing support material usage and removal effort.

Print Parameter Optimization and Quality Control

Layer height, print speed, infill density, temperature settings, and cooling parameters significantly impact prototype quality and printing time. Understanding these parameters enables optimization for specific prototype requirements and material properties while ensuring consistent, repeatable results across multiple print operations.

Advanced parameter optimization includes adaptive layer heights, variable infill patterns, and multi-material printing strategies. Professional printing services optimize parameters for each specific application while maintaining quality standards and meeting project timeline requirements.

Specialized parameter control encompasses high-speed printing, ultra-fine detail reproduction, and large-scale prototype production. This expertise ensures optimal print quality regardless of size, complexity, or material requirements while maintaining efficiency and cost-effectiveness.

Post-Processing Techniques and Surface Finishing

Professional post-processing including support removal, surface finishing, sanding, painting, and assembly preparation transforms raw prints into functional prototypes ready for testing and validation. Advanced finishing techniques enable prototypes that closely match intended production appearance and functionality.

Advanced post-processing encompasses chemical smoothing, vapor polishing, and precision machining of printed parts. Professional finishing services ensure prototypes meet aesthetic and functional requirements while providing appropriate surface textures and dimensional accuracy for testing applications.

Specialized finishing techniques include metal plating, insert installation, and multi-material assembly processes. This expertise enables creation of sophisticated prototypes that combine 3D printed components with traditional manufacturing elements for comprehensive functional validation.

Prototype Testing and Design Iteration Strategies

Systematic testing protocols and design iteration based on prototype performance ensures final products meet functional requirements while identifying areas for improvement before full production. Professional testing services validate design concepts while providing data for optimization and refinement.

Advanced testing approaches include stress analysis, environmental testing, and user experience validation. Professional prototype testing services provide comprehensive evaluation of form, fit, and function while identifying potential manufacturing and performance issues early in the development process.

Specialized testing protocols encompass regulatory compliance validation, safety assessment, and long-term durability evaluation. This expertise ensures prototypes not only meet immediate functional requirements but also provide reliable data for production planning and quality assurance development.