Complete Product Development Process: From Concept to Manufacturing Success

Comprehensive Product Development: Your Complete Guide to Manufacturing Success

Product development is a complex journey that transforms innovative ideas into successful manufactured products. As a freelance product development specialist with extensive manufacturing experience, I guide clients through every stage of this critical process, from initial concept validation to full-scale production implementation. Understanding each phase ensures project success while minimizing risks and optimizing outcomes.

Professional product development services encompass market research, technical feasibility analysis, design optimization, prototyping, testing validation, and manufacturing preparation. This comprehensive approach ensures products not only meet market needs but also achieve manufacturing efficiency, quality standards, and commercial viability throughout their entire lifecycle.

Stage 1: Concept Development and Market Validation

Every successful product begins with thorough concept development that combines innovative thinking with market reality. This critical first stage involves idea generation, market research, competitive analysis, and initial feasibility assessment to ensure concepts have commercial potential before significant resources are invested in development activities.

Professional concept development services include market opportunity analysis, target customer identification, competitive landscape evaluation, and technical feasibility assessment. This comprehensive approach ensures product concepts address real market needs while remaining technically achievable within budget and timeline constraints.

Advanced concept validation techniques encompass customer interviews, market surveys, focus groups, and prototype testing with target users. These methodologies provide critical feedback that shapes product requirements and ensures development efforts focus on features that deliver genuine value to end users and commercial success.

Specialized concept development includes intellectual property research, regulatory requirement analysis, and manufacturing constraint evaluation. This expertise ensures concepts can be protected, comply with applicable standards, and remain manufacturable using available technologies and processes within projected cost targets.

Stage 2: Design Development and Engineering Optimization

Transforming validated concepts into detailed engineering designs requires systematic approach combining aesthetic considerations, functional requirements, manufacturing constraints, and cost optimization. Professional design development ensures products meet performance specifications while remaining manufacturable and commercially viable.

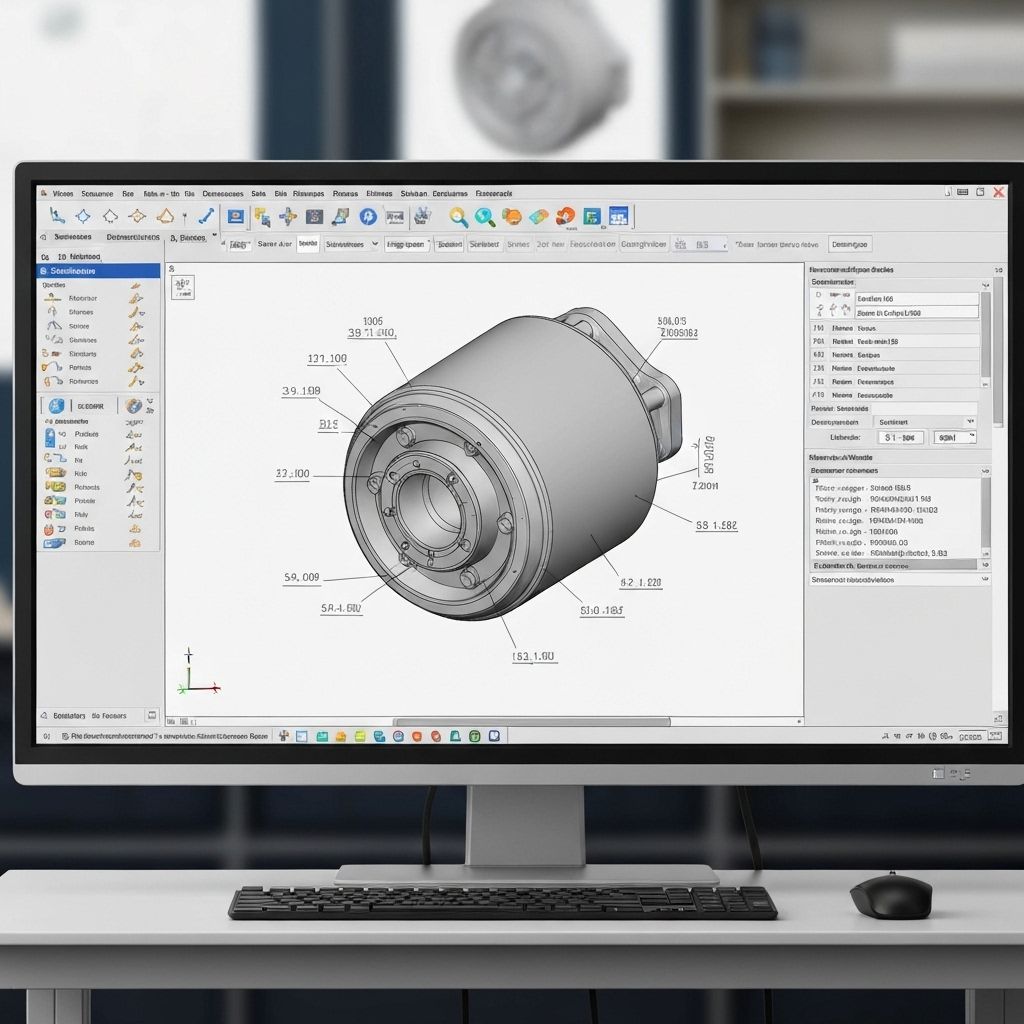

Advanced design development encompasses industrial design, mechanical engineering, materials selection, and manufacturing process optimization. This multidisciplinary approach ensures products achieve optimal balance between form, function, manufacturability, and cost while meeting all performance and regulatory requirements.

Specialized design optimization includes finite element analysis (FEA), computational fluid dynamics (CFD), thermal analysis, and stress testing simulation. These advanced engineering tools validate design performance before physical prototyping, reducing development time and costs while ensuring products meet all functional requirements.

Professional design services also encompass design for manufacturing (DFM), design for assembly (DFA), and design for sustainability (DfS) principles. This comprehensive approach ensures products can be manufactured efficiently, assembled reliably, and disposed of responsibly while maintaining performance and cost targets.

Expert design development includes component standardization, supplier integration, and supply chain optimization strategies. These considerations ensure products can be manufactured consistently using available suppliers and materials while maintaining quality standards and cost competitiveness throughout the product lifecycle.

Stage 3: Prototyping and Iterative Development

Physical prototyping transforms digital designs into tangible products for testing, validation, and refinement. Professional prototyping services utilize advanced manufacturing techniques including 3D printing, CNC machining, injection molding, and sheet metal fabrication to create functional prototypes that accurately represent final product characteristics.

Advanced prototyping strategies encompass rapid prototyping for quick iteration, functional prototyping for performance validation, and production-intent prototyping for manufacturing verification. This systematic approach ensures each prototype serves specific validation purposes while advancing product development toward manufacturing readiness.

Specialized prototyping techniques include multi-material printing, insert molding, overmolding, and hybrid manufacturing processes. These advanced capabilities enable creation of sophisticated prototypes that closely match intended production methods and materials while providing accurate performance data for validation testing.

Professional prototyping services also include prototype testing, performance validation, user experience evaluation, and design iteration based on testing results. This comprehensive approach ensures products meet all functional requirements while identifying opportunities for improvement before production tooling investment.

Expert prototyping encompasses cost analysis, manufacturing feasibility assessment, and supplier capability evaluation. These considerations ensure prototype designs can transition smoothly to production while maintaining performance characteristics and achieving target cost objectives through optimized manufacturing processes.

Stage 4: Manufacturing Implementation and Production Scaling

Transitioning from prototypes to full production requires comprehensive manufacturing planning including process selection, tooling design, supplier qualification, and quality system implementation. Professional manufacturing services ensure smooth production launch while maintaining quality standards and cost targets throughout scaling operations.

Advanced manufacturing implementation encompasses injection molding tooling, die casting setup, sheet metal forming, CNC programming, and assembly line design. This expertise ensures production processes are optimized for efficiency, quality, and scalability while meeting volume and cost requirements for commercial success.

Specialized manufacturing services include supplier development, quality system implementation, statistical process control, and continuous improvement programs. These comprehensive approaches ensure consistent product quality while enabling cost reduction and efficiency improvements throughout the production lifecycle.

Professional manufacturing support also encompasses regulatory compliance, safety certification, environmental compliance, and international standards adherence. This expertise ensures products meet all applicable requirements for target markets while maintaining manufacturing efficiency and quality standards.

Expert manufacturing implementation includes supply chain optimization, inventory management, logistics planning, and distribution strategy development. These considerations ensure products reach customers efficiently while maintaining quality and cost competitiveness in target markets worldwide.

Stage 5: Validation, Testing, and Quality Assurance

Comprehensive testing and validation ensure products meet all performance, safety, and regulatory requirements before market launch. Professional validation services encompass functional testing, durability assessment, environmental testing, and regulatory compliance verification to guarantee product success and customer satisfaction.

Advanced testing methodologies include accelerated life testing, environmental stress screening, electromagnetic compatibility (EMC) testing, and safety certification processes. These comprehensive validation approaches ensure products perform reliably under all intended operating conditions while meeting applicable safety and regulatory standards.

Specialized validation services encompass user acceptance testing, field trials, beta testing programs, and market validation studies. These real-world testing approaches provide critical feedback on product performance, user experience, and market acceptance before full commercial launch.

Professional quality assurance includes statistical quality control, process capability studies, measurement system analysis, and continuous monitoring programs. This systematic approach ensures consistent product quality while enabling early detection and correction of potential quality issues throughout production operations.

Expert validation services also include documentation preparation, certification support, regulatory submission assistance, and compliance verification. This comprehensive approach ensures products meet all requirements for target markets while providing necessary documentation for successful market entry and ongoing compliance maintenance.

Risk Management and Project Success Strategies

Successful product development requires proactive risk management including technical risk assessment, market risk evaluation, manufacturing risk mitigation, and financial risk control. Professional risk management services identify potential issues early while implementing mitigation strategies that ensure project success within budget and timeline constraints.

Advanced risk management encompasses contingency planning, alternative solution development, supplier risk assessment, and intellectual property protection strategies. These comprehensive approaches ensure projects can adapt to changing conditions while maintaining progress toward successful market launch and commercial objectives.

Specialized risk mitigation includes technology risk assessment, regulatory risk evaluation, competitive risk analysis, and market timing considerations. This expertise ensures product development projects navigate complex challenges while maintaining competitive advantage and market positioning for long-term success.

Professional project management services encompass timeline optimization, resource allocation, stakeholder communication, and progress monitoring systems. This systematic approach ensures projects remain on track while adapting to changing requirements and market conditions throughout the development process.

Why Choose Professional Product Development Services

Partnering with experienced product development professionals provides access to specialized expertise, advanced tools, established supplier networks, and proven methodologies that accelerate development while reducing risks and costs. This comprehensive support ensures projects achieve commercial success while meeting all technical and market requirements.

Professional product development services offer objective perspective, technical expertise, manufacturing knowledge, and market insight that internal teams may lack. This external expertise provides valuable guidance while enabling companies to focus on core business activities during product development projects.

Experienced product development specialists bring established relationships with suppliers, manufacturers, testing laboratories, and certification bodies that accelerate project timelines while ensuring quality outcomes. These networks provide access to specialized capabilities and competitive pricing that may not be available to individual companies.

Expert product development support includes ongoing consultation, troubleshooting assistance, optimization recommendations, and continuous improvement guidance throughout the product lifecycle. This long-term partnership ensures products remain competitive while adapting to changing market conditions and customer requirements.