Legacy Drawing Conversion: Modernizing Hand-Drawn Technical Drawings

Modernizing Legacy Technical Documentation for Digital Manufacturing

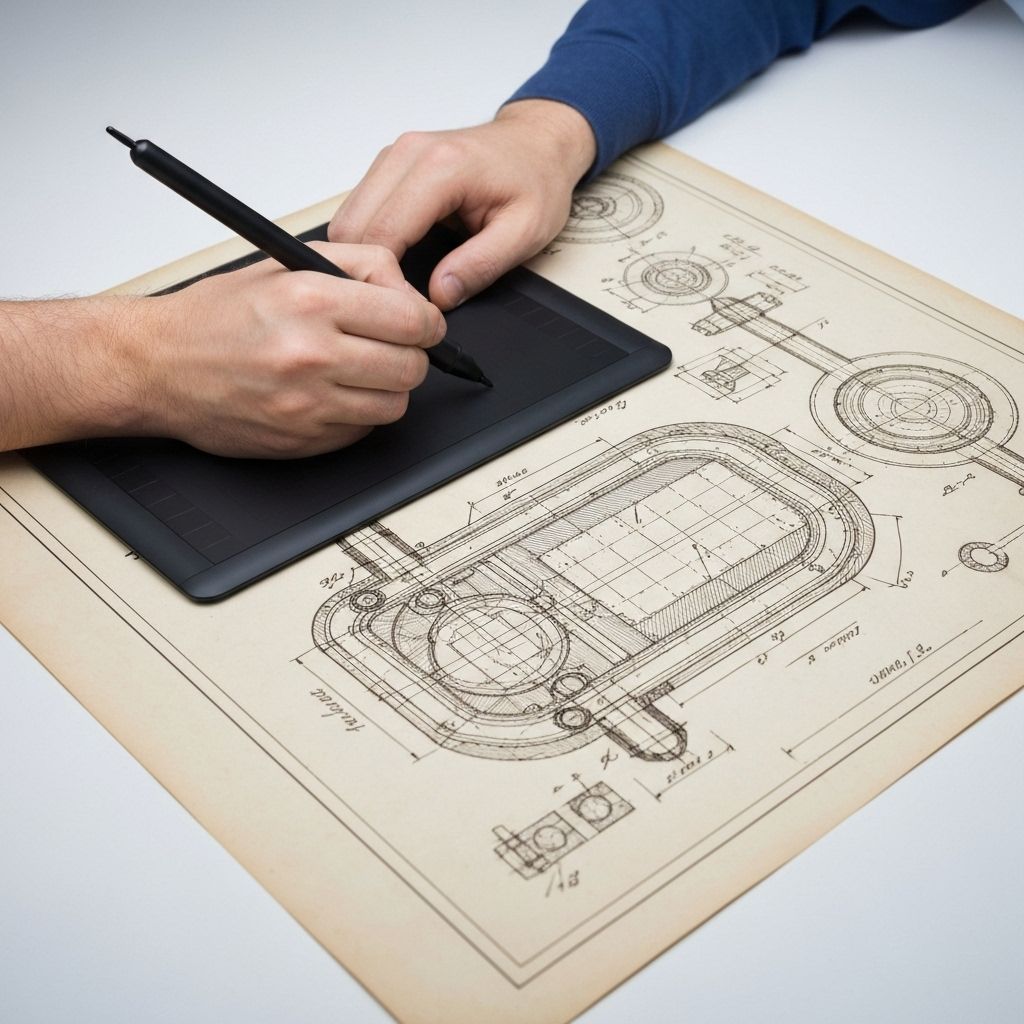

Converting hand-drawn and legacy technical drawings into modern digital formats preserves critical engineering knowledge while improving accessibility and usability for contemporary manufacturing processes. As a freelance drawing conversion specialist, I provide comprehensive services that transform historical documentation into current industry-standard formats while maintaining original design intent and engineering accuracy.

Professional legacy drawing conversion services are essential for companies maintaining older equipment, reproducing discontinued parts, and preserving institutional engineering knowledge. This specialized expertise ensures valuable technical information remains accessible and usable while meeting modern manufacturing and quality control requirements.

Assessment and Digitization Planning Strategies

Successful conversion begins with thorough assessment of existing drawings including condition evaluation, priority ranking, and digitization strategy development. Understanding the original design intent, manufacturing context, and current application requirements is crucial for accurate conversion and optimal resource allocation.

Advanced assessment techniques include drawing condition analysis, information completeness evaluation, and conversion complexity estimation. Professional planning services ensure efficient project execution while maximizing value and minimizing conversion costs through strategic prioritization and resource optimization.

Specialized planning approaches encompass multi-format source material, varying drawing standards, and incomplete documentation challenges. This expertise ensures even the most challenging legacy drawing collections can be successfully converted while maintaining accuracy and completeness.

High-Resolution Scanning and Image Processing Techniques

High-quality scanning using appropriate resolution and color depth captures drawing details accurately while preserving original information content. Advanced image processing techniques including noise reduction, contrast enhancement, and line cleanup improve drawing clarity and readability for efficient conversion processes.

Professional scanning services optimize parameters for different drawing types, paper conditions, and information density requirements. Specialized techniques handle oversized drawings, fragile documents, and multi-layer information while maintaining image quality and dimensional accuracy.

Advanced image processing encompasses automatic line detection, text recognition, and symbol identification to accelerate conversion processes. These sophisticated techniques reduce manual effort while improving accuracy and consistency across large drawing collections.

CAD Reconstruction and Interpretation Techniques

Converting legacy drawings to modern CAD format involves careful interpretation of hand-drawn lines, dimensions, and annotations while understanding historical drafting standards and conventions. This expertise ensures accurate translation to current practices while maintaining original design intent and engineering accuracy.

Advanced reconstruction techniques include parametric modeling, associative dimensioning, and intelligent feature recognition. Professional CAD conversion services create models that are not only accurate but also easily modifiable for future design improvements and manufacturing optimization.

Specialized interpretation approaches handle incomplete information, ambiguous dimensions, and obsolete standards while making appropriate engineering judgments. This expertise ensures converted drawings are both accurate and practical for modern manufacturing applications.

Standards Modernization and Compliance Updates

Updating legacy drawings to current industry standards including ASME Y14.5, ISO specifications, and modern drawing practices improves clarity and ensures compatibility with contemporary manufacturing processes while maintaining original design functionality and performance requirements.

Professional standards modernization includes tolerance conversion, symbol updates, and documentation format improvements. These services ensure converted drawings meet current quality management system requirements while remaining compatible with modern manufacturing and inspection equipment.

Advanced modernization encompasses geometric dimensioning and tolerancing (GD&T) implementation, material specification updates, and surface finish standardization. This comprehensive approach ensures legacy designs meet current performance and manufacturing standards while preserving original functionality.

Digital Archive Management and Accessibility Systems

Implementing proper file organization, naming conventions, and metadata management creates searchable digital archives that preserve engineering knowledge for future generations while enabling efficient retrieval and use. Professional archive management ensures long-term accessibility and usability of converted drawings.

Advanced archive systems include version control, access management, and integration with enterprise document management systems. These comprehensive solutions ensure converted drawings remain accessible and current while maintaining security and audit trail requirements.

Specialized archive management encompasses backup strategies, format migration planning, and long-term preservation techniques. This expertise ensures digital archives remain accessible and usable despite changing technology and organizational requirements.

Quality Control and Validation Processes

Rigorous quality control processes including accuracy verification, completeness checking, and stakeholder review ensure converted drawings maintain original design intent while meeting modern documentation standards. Professional quality assurance prevents errors and ensures successful project outcomes.

Advanced validation techniques include dimensional verification, cross-reference checking, and manufacturing feasibility assessment. These comprehensive quality control processes ensure converted drawings are both accurate and practical for current manufacturing applications.

Specialized quality control encompasses historical accuracy verification, engineering judgment validation, and compliance confirmation. This expertise ensures converted drawings meet all requirements while preserving valuable engineering knowledge and design intent for future applications.