Reverse Engineering: Converting Physical Parts to Accurate CAD Models

Professional Reverse Engineering Techniques and Services

Reverse engineering transforms existing physical parts into accurate CAD models for reproduction, improvement, or documentation purposes. As a freelance reverse engineering specialist, I provide comprehensive services that combine systematic measurement techniques, advanced modeling skills, and deep understanding of manufacturing processes to deliver precise digital representations.

Professional reverse engineering services are essential for legacy part reproduction, competitive analysis, failure investigation, and design improvement projects. This specialized expertise enables companies to maintain critical equipment, improve existing designs, and develop new products based on proven concepts while ensuring dimensional accuracy and functional performance.

Measurement and Data Collection Methodologies

Accurate reverse engineering begins with comprehensive measurement using precision instruments including calipers, micrometers, height gauges, and coordinate measuring machines (CMM). Each measurement method offers unique advantages depending on part complexity, required accuracy, and accessibility constraints.

Advanced measurement techniques include optical comparators, surface profilometers, and portable CMM systems for large or complex parts. Professional measurement services ensure data collection accuracy while documenting measurement uncertainty and traceability for quality assurance purposes.

Specialized measurement approaches encompass thread analysis, surface texture evaluation, and material identification techniques. This comprehensive data collection ensures reverse engineered models capture all critical characteristics necessary for successful reproduction and functional performance.

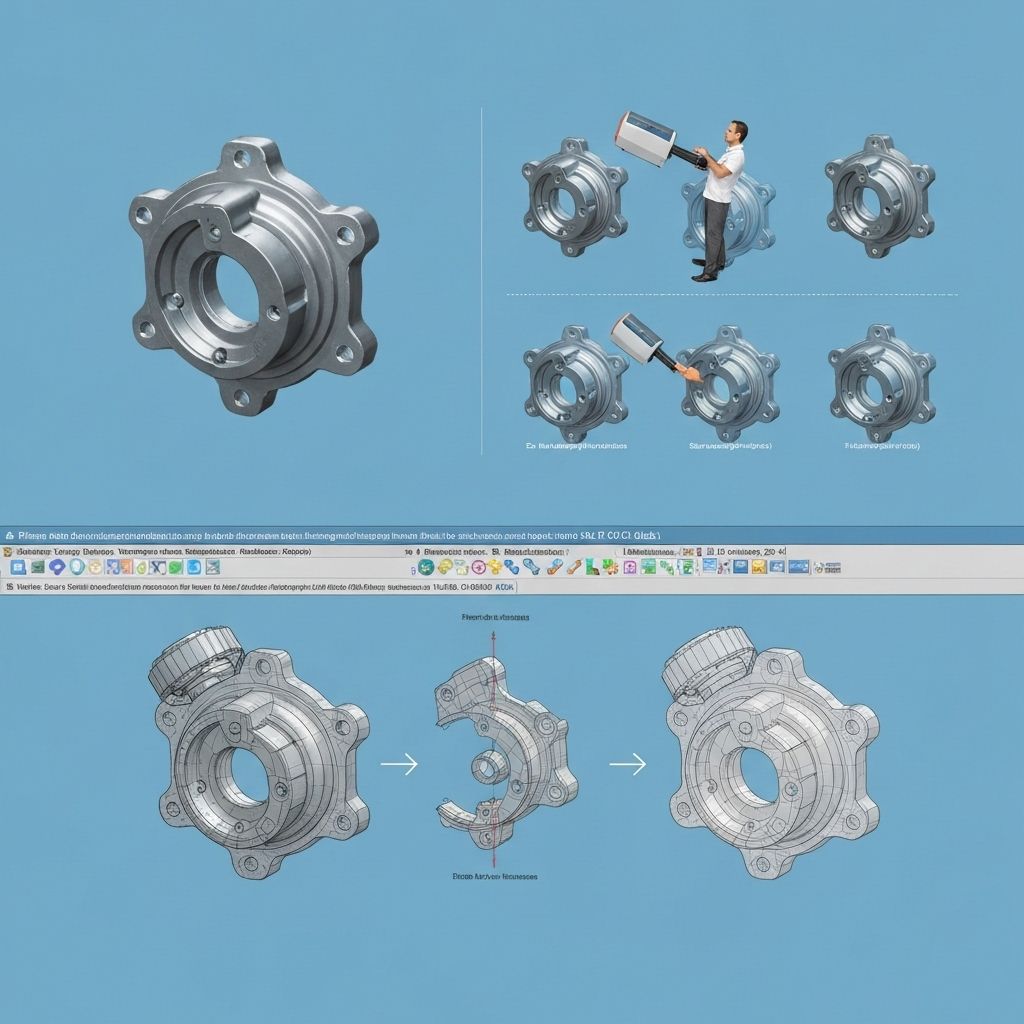

3D Scanning Integration and Point Cloud Processing

Modern 3D scanning technology accelerates the reverse engineering process by capturing complex geometries quickly and accurately. Understanding scan data processing, mesh-to-CAD conversion, and quality validation ensures reliable results while reducing project timelines and improving accuracy for complex surfaces.

Advanced scanning techniques include structured light scanning, laser triangulation, and photogrammetry for different part sizes and accuracy requirements. Professional scanning services optimize scan parameters, lighting conditions, and surface preparation to maximize data quality and minimize post-processing requirements.

Specialized point cloud processing encompasses noise reduction, data alignment, and feature extraction techniques. This expertise ensures scan data is converted efficiently into usable CAD geometry while maintaining dimensional accuracy and surface quality requirements.

CAD Model Reconstruction and Parametric Design

Converting measurement data into parametric CAD models requires strategic feature recognition, proper modeling sequence, and design intent capture. The goal is creating models that are both dimensionally accurate and easily modifiable for future improvements or design variations.

Advanced reconstruction techniques include surface modeling, solid modeling, and hybrid approaches depending on part complexity and intended use. Professional CAD reconstruction services ensure models are optimized for manufacturing while maintaining design flexibility and parametric relationships.

Specialized modeling approaches encompass complex surfaces, multi-body assemblies, and mechanism reconstruction. This expertise enables accurate representation of sophisticated parts and assemblies while maintaining functional relationships and design intent.

Manufacturing-Ready Documentation and Specifications

Reverse engineered parts must include complete manufacturing documentation including technical drawings, material specifications, surface finish requirements, and quality control criteria. This comprehensive documentation ensures successful reproduction while maintaining original part functionality and performance characteristics.

Advanced documentation services include tolerance analysis, manufacturing process recommendations, and supplier qualification criteria. Professional reverse engineering documentation provides manufacturers with complete information for efficient production planning and quality assurance implementation.

Specialized documentation encompasses material testing results, performance specifications, and application requirements. This comprehensive approach ensures reverse engineered parts meet all functional requirements while remaining manufacturable using available processes and materials.

Quality Validation and Verification Processes

Validating reverse engineered models against original parts using inspection techniques and prototype testing ensures accuracy and functionality before full production begins. Professional validation services include dimensional verification, material confirmation, and performance testing to guarantee successful outcomes.

Advanced validation techniques encompass statistical analysis, measurement uncertainty evaluation, and traceability documentation. These comprehensive quality control processes ensure reverse engineered parts meet all requirements while providing confidence in manufacturing outcomes.

Specialized validation services include failure analysis, performance testing, and long-term reliability assessment. This expertise ensures reverse engineered parts not only match original specifications but also meet current performance and safety standards for continued service.