Technical Drawing Standards: Tolerancing and Dimensioning for Manufacturing

Mastering Technical Drawing Standards for Precision Manufacturing

Creating technical drawings that communicate design intent clearly and accurately is fundamental to successful manufacturing. As a freelance technical drawing specialist, I provide comprehensive drafting services following industry-standard practices for tolerancing, dimensioning, and documentation according to ASME Y14.5 and ISO standards.

Professional technical drawing services ensure manufacturing teams receive clear, unambiguous documentation that prevents costly errors and ensures consistent production results. Proper dimensioning and tolerancing practices are essential for maintaining quality control and enabling efficient manufacturing processes across different suppliers and facilities.

Geometric Dimensioning and Tolerancing (GD&T) Expertise

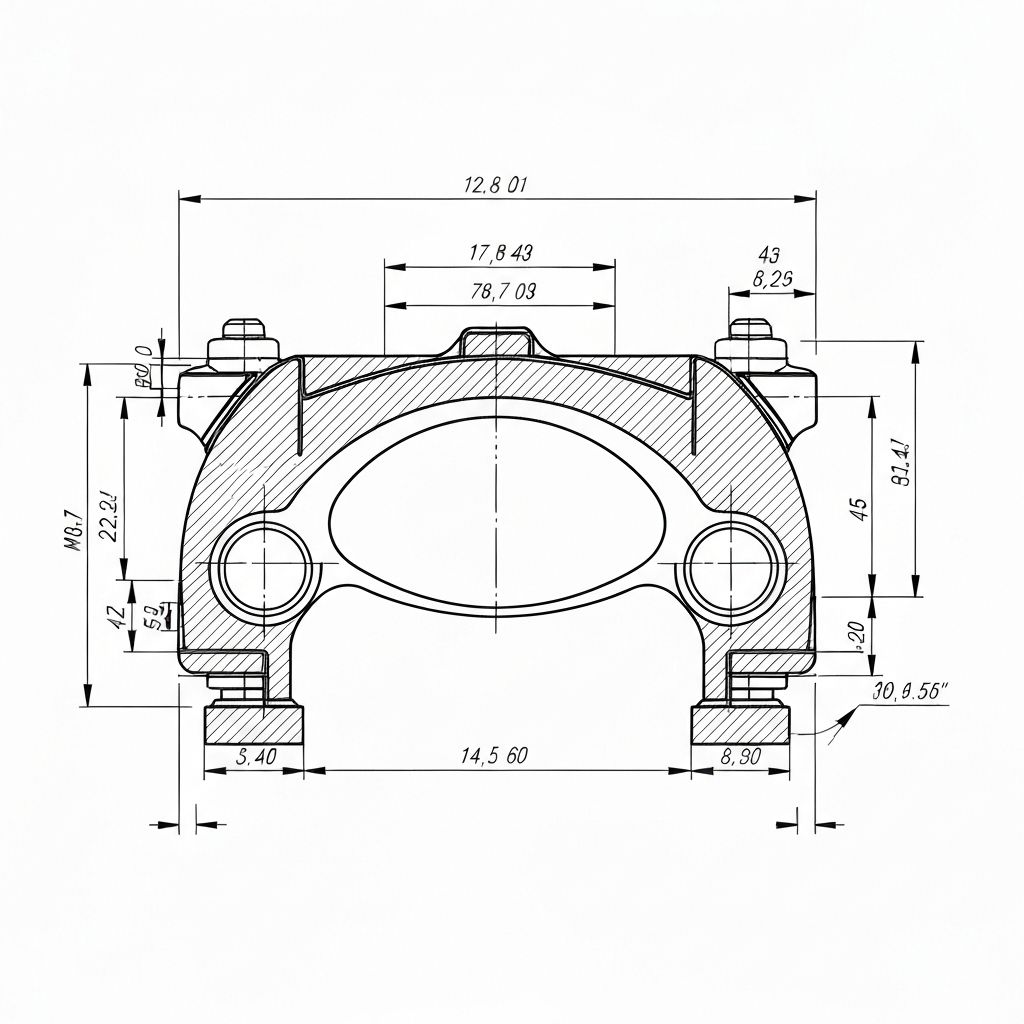

GD&T provides a precise language for communicating design requirements and manufacturing tolerances. Understanding feature control frames, datum references, and geometric tolerances ensures parts function as intended while maintaining manufacturability and enabling efficient inspection processes.

Advanced GD&T application includes position tolerancing, profile controls, runout specifications, and composite tolerancing techniques. Professional GD&T services help optimize tolerance allocation, reduce manufacturing costs, and improve part functionality while ensuring compliance with industry standards and customer requirements.

Freelance GD&T consulting services include tolerance analysis, inspection planning, and manufacturing process optimization. This comprehensive approach ensures geometric requirements are achievable using available manufacturing processes while maintaining functional requirements and quality standards.

ASME Y14.5 vs ISO Standards Comparison and Application

While both ASME Y14.5 and ISO GPS standards serve similar purposes, key differences exist in symbol usage, tolerance interpretation, and documentation practices. Understanding these differences is crucial for international manufacturing collaboration and ensuring drawings are interpreted correctly regardless of geographic location.

ASME Y14.5 emphasizes functional dimensioning and tolerancing with specific rules for datum establishment and tolerance zone interpretation. ISO GPS provides a more comprehensive geometric specification system with detailed rules for uncertainty evaluation and measurement traceability.

Professional technical drawing services include standard selection consultation, ensuring drawings comply with appropriate standards for specific industries, customers, and manufacturing locations. This expertise prevents confusion and ensures consistent interpretation across different manufacturing partners and quality control systems.

Sheet Metal Fabrication Drawing Requirements

Sheet metal drawings require specific considerations including bend radii specifications, material thickness callouts, welding symbols, and surface finish requirements. Proper documentation ensures consistent fabrication results across different suppliers while maintaining structural integrity and aesthetic requirements.

Advanced sheet metal drawing techniques include flat pattern documentation, bend allowance specifications, and forming operation sequences. Professional sheet metal drafting services ensure fabricators receive complete information for efficient production planning and quality control implementation.

Specialized sheet metal documentation includes weldment drawings, assembly sequences, and inspection requirements. This comprehensive approach ensures complex fabrications are produced correctly while maintaining dimensional accuracy and structural performance requirements.

Machining Documentation Best Practices and Standards

Precision machined parts demand detailed documentation including surface finish requirements, critical dimensions, inspection criteria, and material specifications. Clear communication prevents manufacturing errors and ensures quality outcomes while enabling efficient production planning and cost estimation.

Advanced machining documentation includes tool specifications, cutting parameters, and workholding requirements. Professional machining drawings provide machinists with complete information for efficient setup and production while maintaining dimensional accuracy and surface quality requirements.

Specialized machining documentation encompasses multi-axis operations, complex geometries, and tight tolerance requirements. This expertise ensures even the most challenging parts can be manufactured successfully using appropriate equipment and techniques while maintaining quality standards.

Digital Drawing Management and Revision Control

Modern manufacturing relies on digital drawing distribution and revision control systems. Implementing proper file formats, naming conventions, and change management processes ensures drawing integrity throughout the product lifecycle while enabling efficient collaboration and version control.

Professional digital drawing services include PDF optimization, CAD file management, and electronic signature implementation. These systems ensure drawings remain accessible and current while maintaining security and traceability requirements for quality management systems.

Advanced drawing management encompasses automated revision tracking, change notification systems, and integration with enterprise resource planning (ERP) systems. This comprehensive approach ensures all stakeholders have access to current drawing information while maintaining audit trails and compliance requirements.