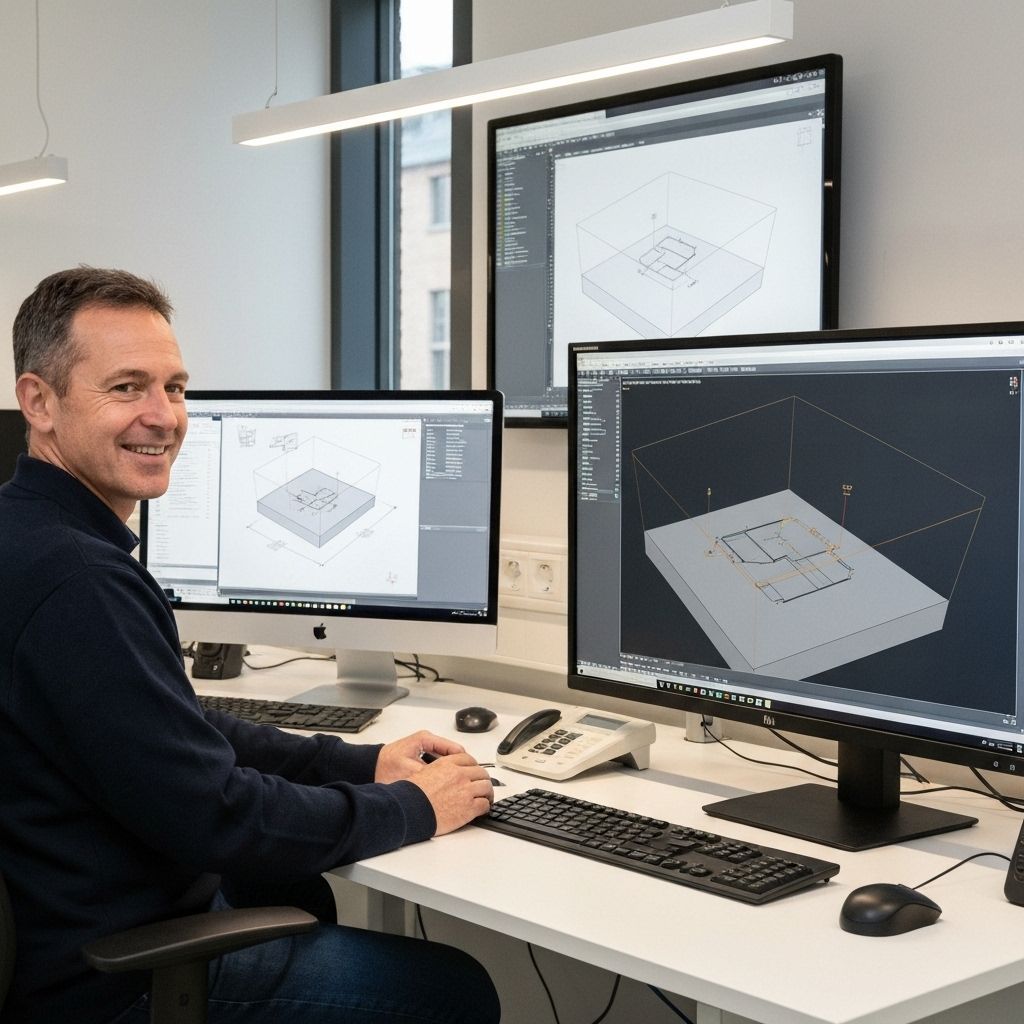

Why Updated 3D and 2D CAD Models Are Essential for Efficient Business Operations

The Critical Role of Updated CAD Documentation in Modern Manufacturing

In today's competitive manufacturing landscape, maintaining current and accurate 3D CAD models and 2D technical drawings is not just beneficial—it's essential for business survival and growth. Updated CAD documentation serves as the foundation for efficient operations, cost control, quality assurance, and strategic decision-making across all aspects of modern manufacturing and product development.

Professional CAD design services ensure your technical documentation remains current, accurate, and optimized for manufacturing efficiency. This comprehensive approach to design management reduces operational costs, minimizes production delays, and enables rapid response to market opportunities while maintaining the highest quality standards throughout your manufacturing processes.

Streamlined Manufacturing Operations Through Current CAD Documentation

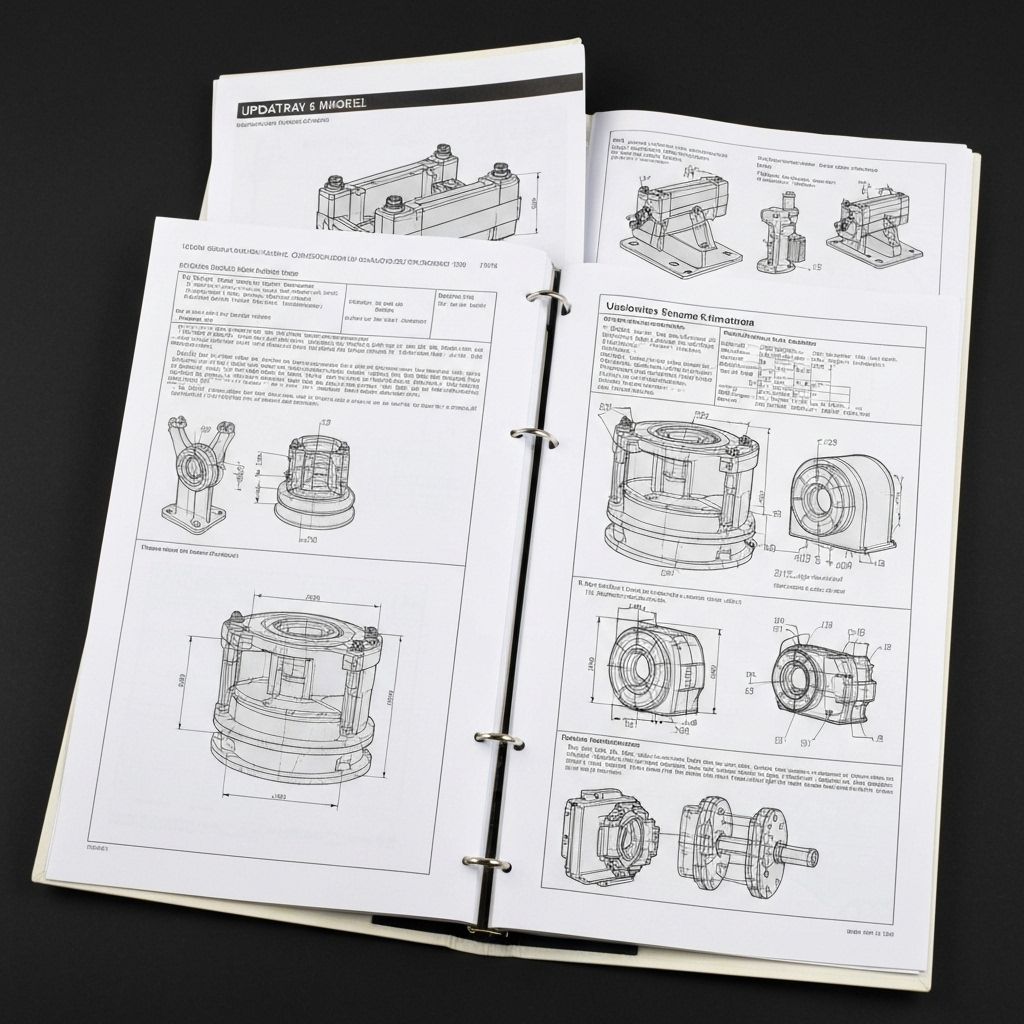

Updated 3D CAD models and 2D technical drawings eliminate confusion on the manufacturing floor by providing clear, accurate instructions for production teams. When drawings reflect current specifications, tolerances, and manufacturing processes, workers can execute tasks efficiently without delays caused by outdated information or conflicting documentation that leads to costly mistakes and rework.

Modern CAD design practices include real-time updates, version control, and automated distribution systems that ensure all stakeholders access the most current information. This systematic approach to design management prevents the use of obsolete drawings, reduces manufacturing errors, and enables consistent quality across all production runs while maintaining traceability for quality control purposes.

Professional 2D drafting services and 3D modeling expertise ensure technical drawings communicate design intent clearly while incorporating manufacturing feedback and process improvements. This collaborative approach between design and production teams results in optimized manufacturing processes that reduce cycle times, minimize waste, and improve overall operational efficiency.

Advanced CAD documentation includes detailed manufacturing instructions, assembly sequences, and quality control checkpoints that guide production teams through complex processes. This comprehensive approach ensures consistent results while enabling new employees to understand manufacturing requirements quickly, reducing training time and improving productivity across all skill levels.

Significant Cost Reduction Through Design Optimization and Error Prevention

Maintaining current CAD models and technical drawings dramatically reduces manufacturing costs by preventing expensive errors, minimizing rework, and optimizing material usage. Updated documentation enables accurate cost estimation, efficient procurement planning, and waste reduction strategies that directly impact profitability while maintaining quality standards and delivery schedules.

Professional CAD design services include design for manufacturing (DFM) analysis that identifies cost-saving opportunities through material optimization, process simplification, and component standardization. This expertise ensures products are designed for efficient manufacturing while maintaining performance requirements and quality standards that meet customer expectations.

Advanced 3D modeling techniques enable virtual prototyping and simulation that identifies potential issues before physical production begins. This proactive approach prevents costly tooling changes, reduces prototype iterations, and accelerates time-to-market while ensuring products meet all functional and quality requirements from the first production run.

Updated technical drawings facilitate accurate supplier quotations and procurement planning by providing clear specifications and requirements. This precision in documentation prevents misunderstandings that lead to incorrect materials, wrong components, or manufacturing delays that increase costs and impact delivery schedules.

Comprehensive CAD documentation enables efficient inventory management through accurate bills of materials (BOMs), component specifications, and usage tracking. This systematic approach reduces excess inventory, prevents stockouts, and optimizes purchasing decisions while maintaining production continuity and customer satisfaction.

Enhanced Quality Control and Consistency Through Precise Documentation

Current CAD models and technical drawings provide the foundation for effective quality control systems by establishing clear specifications, tolerances, and inspection criteria. Updated documentation ensures quality control teams have accurate references for measurement, validation, and acceptance testing that maintain consistent product quality across all production batches.

Professional 2D drafting services include geometric dimensioning and tolerancing (GD&T) specifications that communicate quality requirements precisely to manufacturing and inspection teams. This standardized approach eliminates ambiguity in quality standards while enabling efficient inspection processes that verify conformance to design requirements.

Advanced 3D CAD modeling enables virtual inspection and measurement that validates designs before production begins. This capability identifies potential quality issues early in the development process, preventing defects and ensuring products meet all specifications while reducing inspection time and costs during production.

Updated CAD documentation supports statistical process control (SPC) and continuous improvement initiatives by providing accurate baselines for measurement and analysis. This data-driven approach enables identification of process variations, optimization opportunities, and quality trends that guide improvement efforts and maintain competitive advantage.

Comprehensive technical drawings include inspection instructions, measurement techniques, and acceptance criteria that ensure consistent quality evaluation across different operators and shifts. This standardization reduces variability in quality assessment while maintaining high standards and customer satisfaction throughout all production operations.

Accelerated Product Development and Innovation Through Current Design Assets

Updated 3D CAD models serve as valuable assets for new product development by providing proven design elements, standard components, and manufacturing processes that accelerate innovation cycles. Current documentation enables rapid prototyping, design iteration, and concept validation that reduces development time while maintaining quality and manufacturability standards.

Professional CAD design services create parametric models and design libraries that enable efficient customization and variant development. This systematic approach to design reuse reduces engineering time, ensures consistency across product lines, and enables rapid response to customer requirements and market opportunities while maintaining design integrity.

Advanced 3D modeling capabilities include simulation and analysis tools that validate new designs quickly and accurately. This virtual testing approach identifies optimization opportunities, prevents design flaws, and ensures new products meet performance requirements while reducing physical testing time and costs during development.

Current technical drawings facilitate collaboration between design, manufacturing, and quality teams by providing common references and communication tools. This integrated approach ensures all stakeholders understand design requirements, manufacturing constraints, and quality standards that guide successful product development and launch.

Updated CAD documentation enables efficient engineering change management through version control, impact analysis, and systematic implementation processes. This controlled approach to design changes ensures modifications are implemented correctly while maintaining product integrity and manufacturing efficiency throughout the product lifecycle.

Improved Supply Chain Coordination and Vendor Management

Current CAD models and technical drawings enable effective supplier communication by providing clear specifications, quality requirements, and manufacturing instructions. Updated documentation ensures vendors understand exact requirements while enabling accurate quotations, delivery planning, and quality assurance that maintains supply chain efficiency and reliability.

Professional technical drawing services include supplier-specific documentation that addresses unique capabilities, processes, and quality systems. This customized approach ensures each vendor receives appropriate information while maintaining consistency in quality standards and delivery requirements across the entire supply chain network.

Advanced 3D CAD models enable virtual collaboration with suppliers through shared design platforms and real-time updates. This digital approach accelerates communication, reduces misunderstandings, and enables rapid problem resolution while maintaining design security and intellectual property protection throughout supplier relationships.

Updated documentation supports supplier qualification and audit processes by providing clear standards and expectations for quality, delivery, and performance. This systematic approach ensures suppliers meet requirements while enabling continuous improvement and relationship development that strengthens supply chain resilience and competitiveness.

Comprehensive CAD documentation includes packaging, shipping, and handling instructions that ensure products reach customers in perfect condition. This attention to detail throughout the supply chain prevents damage, reduces returns, and maintains customer satisfaction while optimizing logistics costs and delivery performance.

Regulatory Compliance and Certification Support Through Accurate Documentation

Updated CAD models and technical drawings provide essential documentation for regulatory compliance, safety certifications, and industry standards adherence. Current documentation ensures products meet all applicable requirements while enabling efficient certification processes that maintain market access and customer confidence in product safety and performance.

Professional CAD design services include regulatory requirement analysis and compliance verification that ensures designs meet applicable standards from initial concept through production. This proactive approach prevents costly redesigns and certification delays while maintaining product integrity and market competitiveness throughout the development process.

Advanced technical drawing practices include safety documentation, warning labels, and compliance markings that meet regulatory requirements for different markets and applications. This comprehensive approach ensures products can be sold globally while maintaining consistent safety standards and regulatory compliance across all jurisdictions.

Updated documentation supports audit processes and regulatory inspections by providing complete traceability and design rationale. This systematic approach demonstrates compliance while enabling efficient regulatory interactions that maintain certifications and market access without disrupting business operations.

Comprehensive CAD documentation includes change control processes and impact analysis that ensure regulatory compliance is maintained throughout product modifications and improvements. This controlled approach prevents compliance issues while enabling continuous product development and market responsiveness.

Digital Transformation and Future-Ready Operations

Modern CAD systems enable digital transformation initiatives including cloud-based collaboration, automated workflows, and integrated manufacturing systems. Updated 3D models and 2D drawings serve as the foundation for Industry 4.0 implementations that optimize operations, reduce costs, and improve competitiveness through advanced manufacturing technologies and data analytics.

Professional CAD design services include digital asset management and data integration that enables seamless information flow between design, manufacturing, and business systems. This integrated approach eliminates data silos while enabling real-time decision-making and operational optimization that maintains competitive advantage in rapidly changing markets.

Advanced 3D modeling capabilities support additive manufacturing, automated assembly, and robotic systems that require precise digital definitions for optimal performance. Current CAD documentation enables these advanced manufacturing technologies while maintaining flexibility for future technology adoption and process improvement initiatives.

Updated technical drawings facilitate digital twin implementations and simulation-based optimization that improve operational efficiency and predictive maintenance capabilities. This data-driven approach enables proactive management of manufacturing assets while optimizing performance and reducing downtime throughout facility operations.

Comprehensive CAD documentation supports artificial intelligence and machine learning applications that optimize design, manufacturing, and quality processes. This forward-looking approach ensures businesses remain competitive while leveraging emerging technologies for continuous improvement and operational excellence.

Strategic Investment in Professional CAD Design Services

Partnering with experienced CAD design professionals ensures your technical documentation remains current, accurate, and optimized for business success. Professional 3D modeling and 2D drafting services provide the expertise, tools, and processes necessary to maintain competitive advantage while reducing costs and improving operational efficiency across all aspects of your manufacturing operations.

Expert CAD design services offer objective analysis, industry best practices, and advanced techniques that internal teams may lack. This external expertise provides valuable insights while enabling companies to focus on core business activities while ensuring technical documentation supports strategic objectives and operational excellence.

Professional CAD design partnerships include ongoing support, technology updates, and continuous improvement guidance that ensures documentation systems remain current and effective. This long-term relationship provides stability and expertise while adapting to changing business requirements and technological advances throughout your company's growth and development.

Investing in updated CAD models and technical drawings through professional services delivers measurable returns through reduced costs, improved quality, faster development cycles, and enhanced competitiveness. This strategic approach to design management ensures sustainable business growth while maintaining the highest standards of technical excellence and operational efficiency.